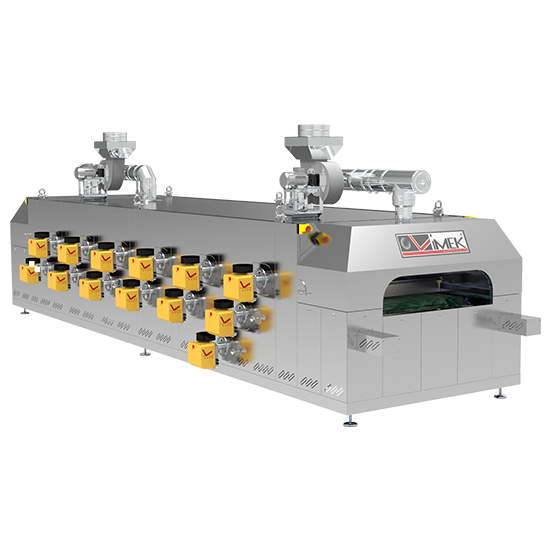

Tunnel Ovens

Homogeneous cooking and quality products

See other pictures

Solidity and reliability are the two fundamental prerogatives of all our tunnel ovens, designed to ensure the homogeneous cooking of food and guarantee quality products. The design of the oven is based on three elements: type of product, required temperature and hourly production.

Each solution is equipped with an intuitive touch screen that allows the customer to manage each section of the oven independently, setting independent temperatures allowing the achievement of a personalized cooking that satisfies any need.

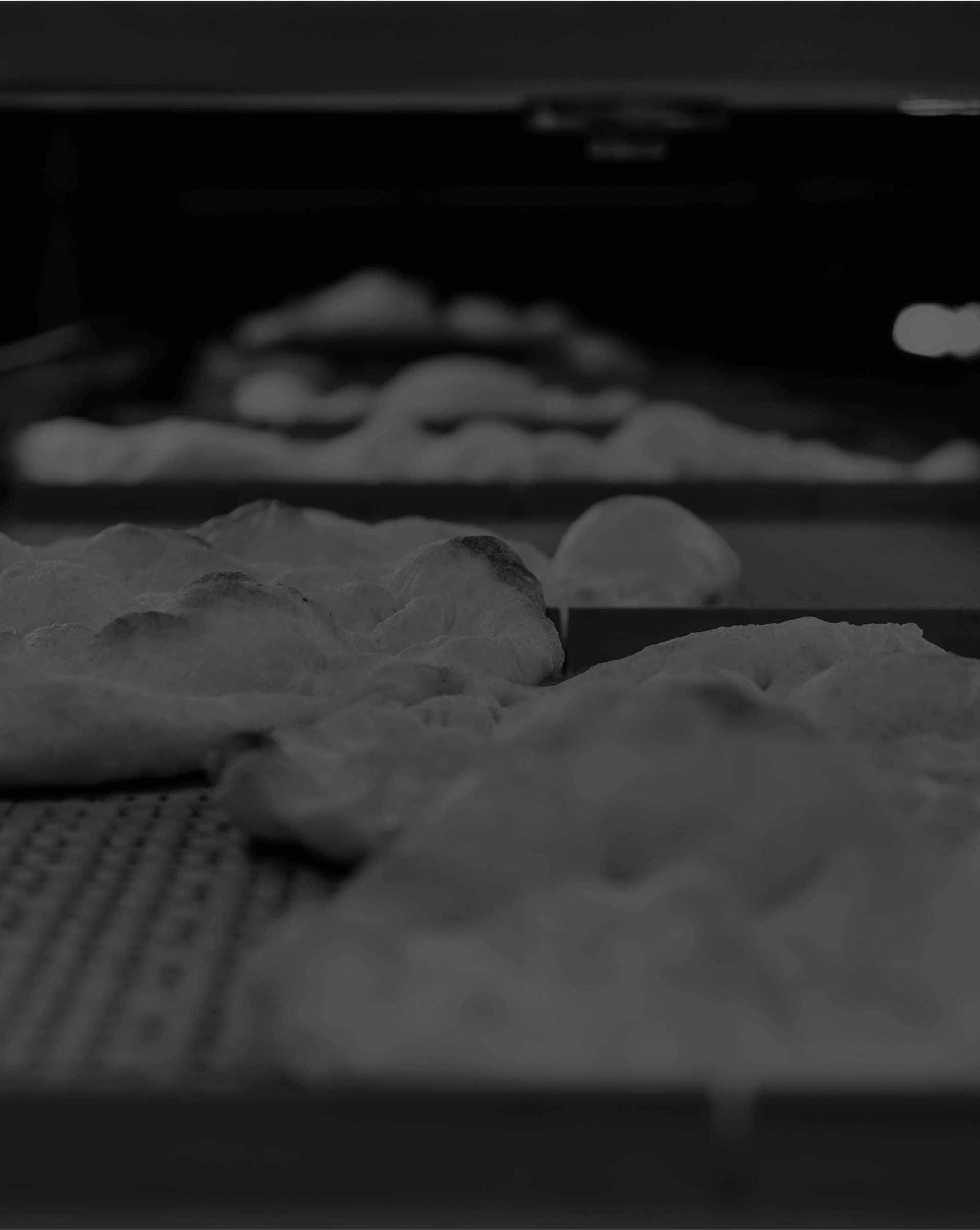

DIRECT FLAME OVEN

Perfect for artisanal baking, our direct flame ovens with gas burners are characterized by a flame in the cooking chamber which guarantees direct radiation of the product.

ELECTRIC OVEN

In electric resistance ovens for food production, cooking takes place by direct irradiation of the product. The special armored resistances are specially made to ensure homogeneous cooking of the product.

HEAT-CYCLE OVENS

Our thermal cycle ovens are designed for indirect irradiation of the product. The heat created in the combustion chambers and conveyed into special cavities, makes it possible to cook the product slowly and evenly.

FEATURES

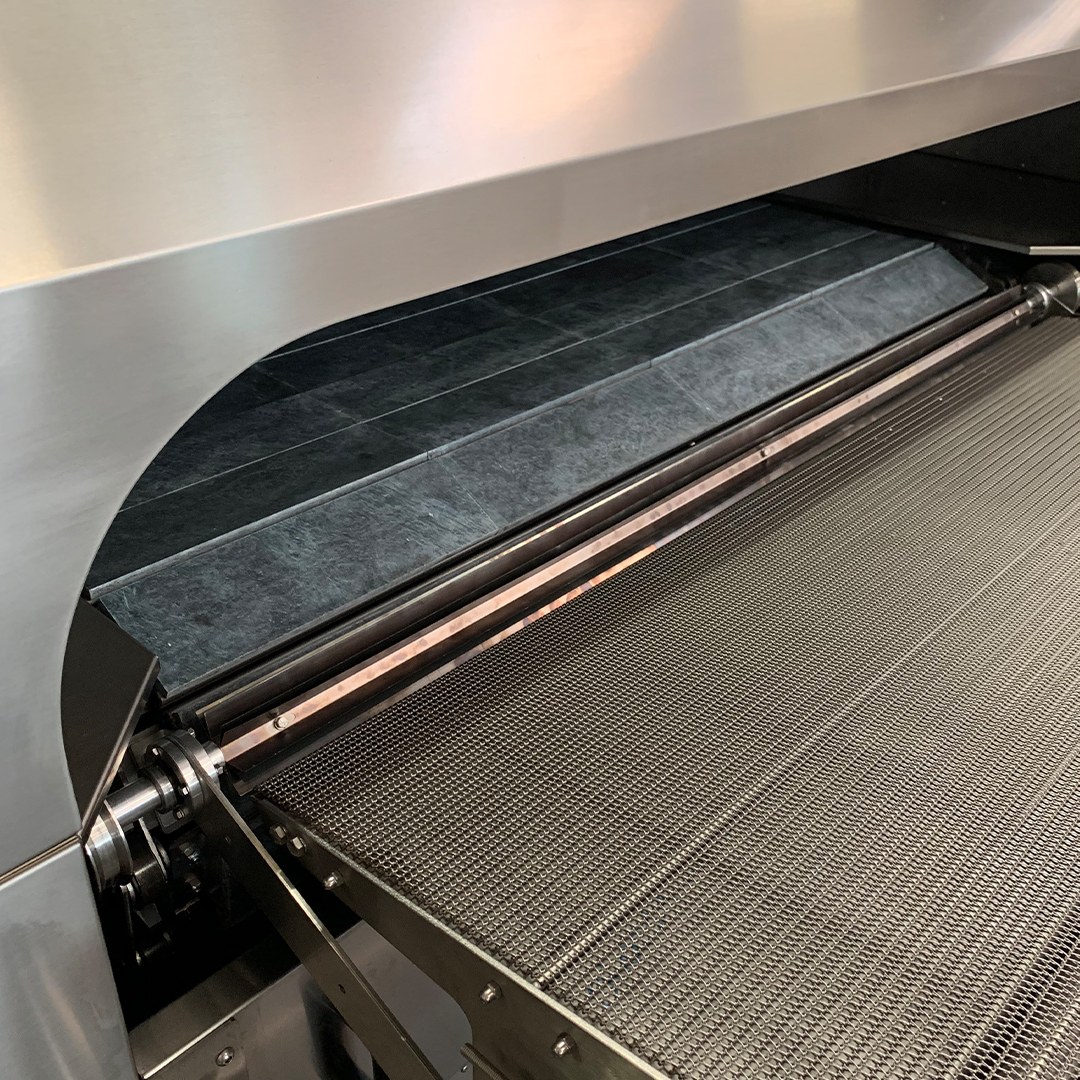

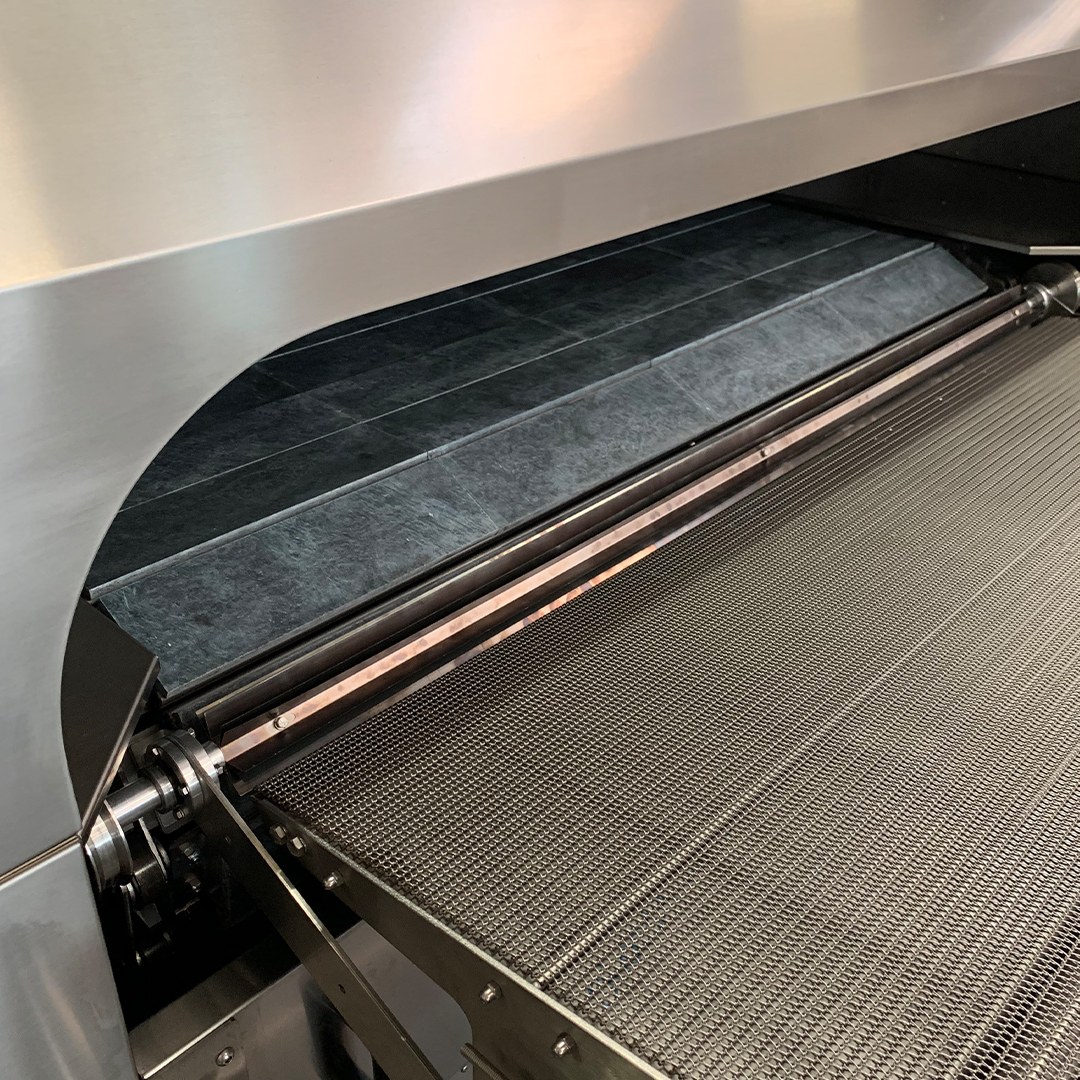

Conveyors

Marble Stone: material suitable for cooking pizza and Arabic bread, characterized by very high thermal performance and easy to clean.

Fire Stone: Composed of a set of high temperature stones, the heat conduction is similar to marble.

Steel Plate: it is the perfect solution for products that require rapid cooking without the risk of being damaged due to temperature variations, excellent value for money.

Wire Mesh: thanks to very low heat conduction it is the ideal solution for products intended for packaging, such as baked confectionery products, which do not require a high temperature impact from below.

Insulation

In order to ensure correct heat retention inside the cooking chamber and, consequently, a minimization of the impact on the working environment, all our ovens for the food industry are supplied with solid rock wool insulation.

Chain Movement

The tensioning system is positioned at the entrance of our industrial tunnel ovens for food, which is carried out by means of pneumatic pistons. At the out feed, however, there’s the drive device, connected directly to the main rod, whose speed can be adjusted via the control panel.

Control

All our ovens for the food industry are equipped with an electrical panel for the management, via touch screen, of all parameters such as temperatures, belt speed, recipes and more, ensuring maximum performance in terms of cooking.

Do you want more information?