Vimek Bakery Automation

Machines

Spirals

Our spiral plants for thermic treatments involved in the production phases of food products are technologically advanced, versatile and reliable.

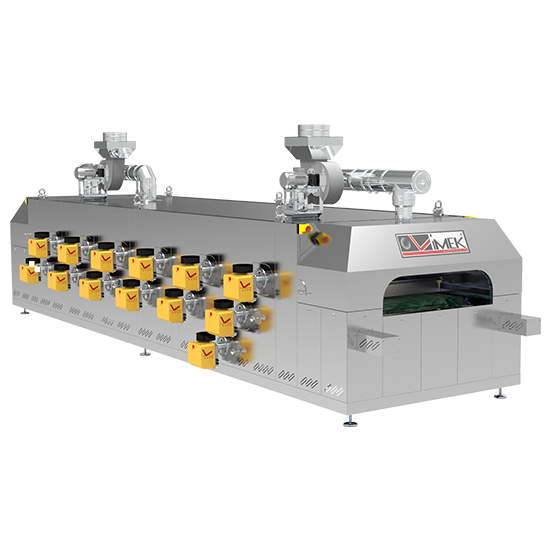

Tunnel Oven

Solidity and reliability are the two fundamental prerogatives of all our tunnel ovens, designed to ensure the homogeneous cooking of food and guarantee high-quality products.

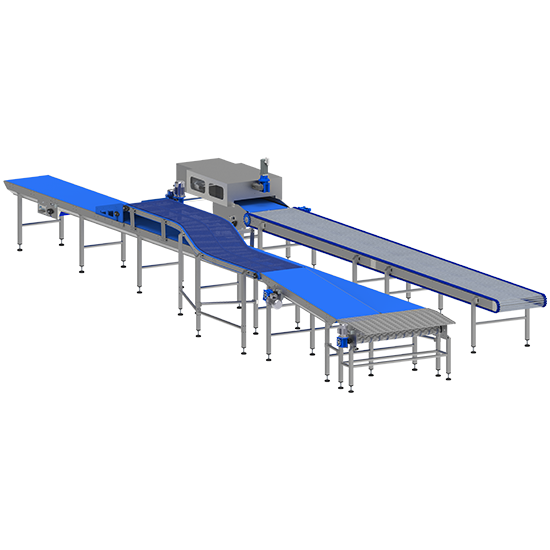

Conveyors

In collaboration with leading companies in the food industry machinery field, we design transport systems suitable for any type of use.

Do you want more information?

Contact us for information

Do you want more information?